Advancell is a family of acrylic shells commonly used for foam, adhesion and texturing applications. Our premiere product family is Advancell Expandable Microspheres, or Advancell EM.

Products

| Particle Grade | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Grade | EML101 | EMH204 | EHM302 | EHM303 | EM306 | EM308 | EM403 | EM406 | EM501 | EM504 | EM505 |

| Average Particle Size | 14±5 | 40±5 | 20±5 | 30±5 | 26±5 | 40±5 | 28±5 | 30±5 | 26±5 | 17±5 | 25±5 |

| Expansion Start Temperature (Ts,℃) | 125±10 | 115±10 | 135±10 | 125±10 | 140±10 | 120±10 | 165±10 | 150±10 | 170±10 | 170±10 | 210±10 |

| Maximum Expansion Temperature (Tmax, ℃) | 160±10 | 165±10 | 160±10 | 160±10 | 170±10 | 180±10 | 200±10 | 190±10 | 210±10 | 200±10 | 220±10 |

| True Specific Gravity After Expansion | 0.017±0.005 | 0.013±0.005 | 0.016±0.005 | 0.016±0.005 | 0.016±0.005 | 0.013±0.005 | 0.016±0.005 | 0.016±0.005 | 0.016±0.005 | 0.020±0.005 | 0.016±0.005 |

| Master Batch Grade | |||

|---|---|---|---|

| Grade | P403M1 | P501E2 | P504E2 |

| Microsphere | EM403 | EM501 | EM504 |

| Content (%) | 50 | 30 | 30 |

| Base Resin | EMMA | LDPE | LDPE |

*Base material

ADVANCELL EM

High-Quality Expansion Effect

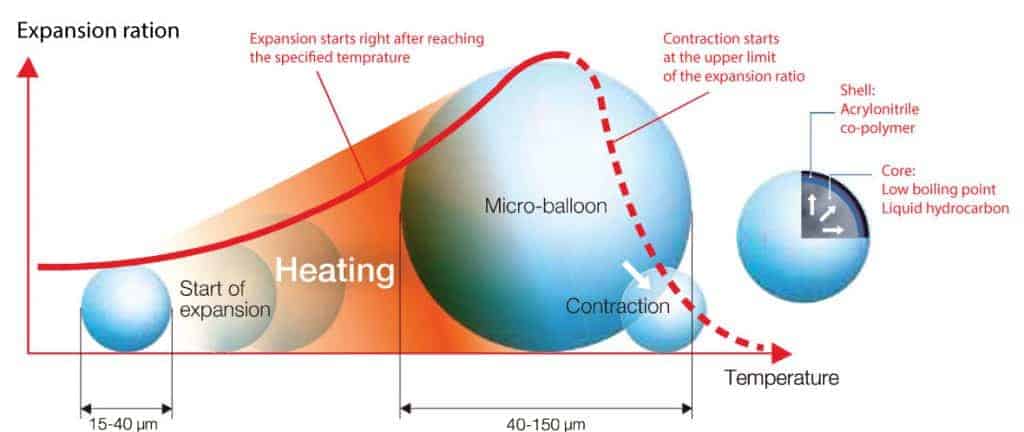

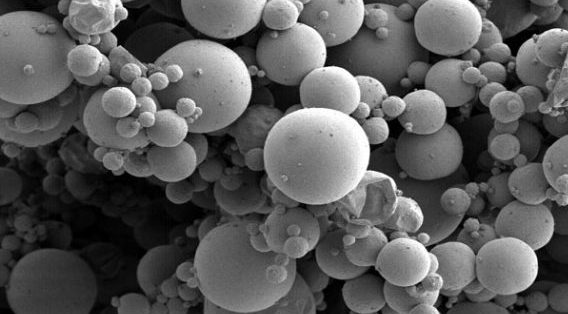

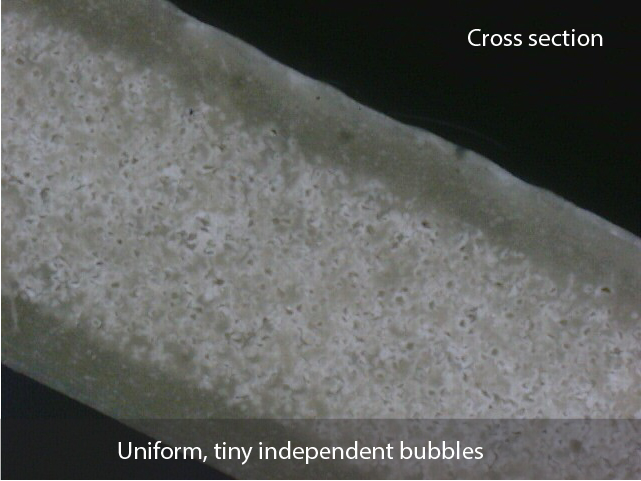

Advancell EM comprises thermo-expandable microspheres (tiny plastic spheres) containing a low-boiling-point liquid hydrocarbon inside a thermoplastic polymer shell. When heated, the shell softens and the hydrocarbon inside expands suddenly, forming micro-balloons.

Mixing Advancell EM with a resin base material adds multiple desirable characteristics and features to the product, such as reduced weight and enhanced flexibility. Selecting an appropriate grade can optimize the expansion start temperature and cell size, which is one of the product’s unique features.

Advantages Over Conventional Chemical Foaming Agents

Because Advancell EM comprises shells (polymer cells), the micro-balloons have an independent, closed-cell structure. As a result, Advancell EM offers many advantages over a chemical foaming agent made mainly of azodicarbonamide (ADCA).

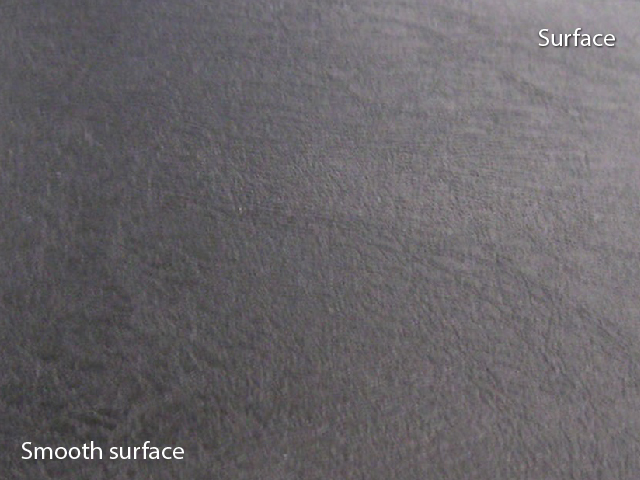

Thanks to SEKISUI’s patented particle dispersion technology, the expansion of Advancell EM is more uniform than that of conventional polymer cells of the same type. This is due to the sharp particle size distribution, which produces a smooth, refined finish. Because Advancell EM maintains a constant amount of heat necessary for expansion and stabilizes the expansion start temperature, controlling the overall processing temperature is easier.

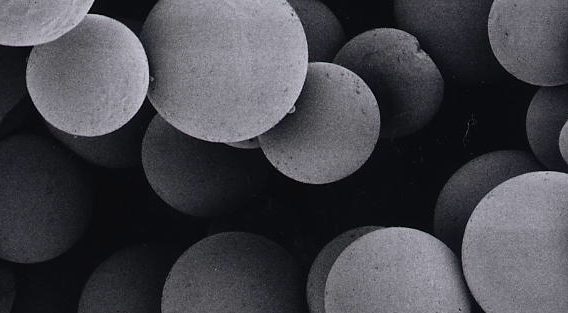

Advancell EM

The Results of Uniform Micro-Balloons

- Uniform cell formation

- Smooth, refined finish

- Expansion loss reduction, requiring only a small amount of added Advancell EM

- Easy-to-control processing temperature

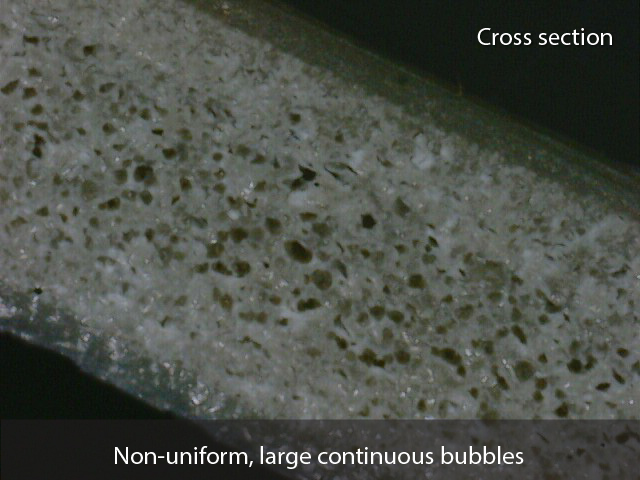

Conventional (Polymer Cell Type)

The Results of Non-Uniform Expansion

- Irregular cell formation

- Rough finish

- Expansion loss generation due to unexpanded particles

- Difficult-to-control processing temperature

Advancell EM

Chemical Foaming Agent